Acorn Beekeeping Equipment, LLC

Acorn Beekeeping Equipment was started in 2013 to satisfy the needs of commercial, sideliner, and backyard beekeepers worldwide. We had one goal—design and produce the highest quality one-piece plastic bee frames, foundations, and drone combs on the market.

We think that bees deserve the best because of the vital role they play in human survival. Everyone knows that bees produce high-quality food-honey and jellies. But did you know that beeswax, propolis, and honey bee venom are used in healthcare products? Still, the greatest contribution bees make is the pollination of nearly three-quarters of the plants that produce 90% of the world's food.

Our frames, foundations, and drone combs are produced and waxed in our California plant.

Our frames, foundations, and drone combs are produced and waxed in our California plant.All of our products are custom molded and waxed in our California plant. We use only 100% pure, high-quality domestic beeswax. Our commitment to quality is why we sell over one million frames and foundations each year, and why our products are used around the world.

Happy bees enjoying their home on an Acorn Beekeeping Equipment® frame.

Happy bees enjoying their home on an Acorn Beekeeping Equipment® frame.Acorn Engineering Company

City of Industry, CA 91746 USA

Acorn Engineering Company has been a manufacturer of stainless steel plumbing fixtures and hand washing stations for institutional, correctional, and commercial use since 1954.

Among the Acorn® product lines are Secur-Care® Ligature-Resistant plumbing fixtures. These fixtures are designed to keep inmates safe and provide security, as well as helping them transition to a normal life.

Acorn also offers a wide variety of hand washing products. Acorn washbasins offer durability, style, and flexibility when outfitting commercial restrooms. Single units made of heavy-gage stainless steel are ideal for institutional and commercial applications. Multi-user stations are available in a variety of materials and designs, including stainless steel and solid surface. Portable units are available for applications where handwashing may need to be moved from place to place.

Acorn Engineering Company Headquarters, City of Industry, CA.

Acorn Engineering Company Headquarters, City of Industry, CA.Shower-Ware® fixtures comprise one of our longest-running product lines. With an emphasis on durability, Shower-Ware fixtures are crafted from heavy gauge stainless steel and are designed to maximize the available space to simultaneously accommodate as many bathers as possible. Applications range from commercial and parks and recreation settings to institutional environments like hospitals, schools, and correctional facilities

Acorn products are known and trusted for their longevity, durability, and reliability. Acorn leverages its engineering ingenuity and experience to create effective solutions to industry needs and can custom make products to exact specifications.

Vari-slab® configurable basin, 9220 series. Vari-slab® basins are constructed from Corterra® solid-surface material.

Vari-slab® configurable basin, 9220 series. Vari-slab® basins are constructed from Corterra® solid-surface material.Acorn-Gencon Plastics, LLC

Acorn-Gencon® Plastics started out molding all the plastic parts for the MGI family of companies. Since 1972, we've been providing complete injection molding solutions, from concept to completion, for enterprise-level manufacturers to entrepreneurs.

With one of the greatest diversities of press sizes in the industry, we are equipped to provide precision molding with tight tolerances for the electronics industry as well as large-tonnage molding.

Our injection molding presses range in size from 55 to 750-tons with state-of-the-art hot stamping equipment and secondary work areas.

Our injection molding presses range in size from 55 to 750-tons with state-of-the-art hot stamping equipment and secondary work areas.For companies looking to have parts manufactured in the USA, we offer a unique advantage. We are located in Chino, CA—just outside of Los Angeles, and a short distance from major ports and distribution centers.

Besides molding, we also do assembly, packaging, warehousing, and with Amazon distribution centers only 20 minutes from our facility, we can run drop shipments direct each day, making us a one-stop shop for entrepreneurs.

Whether you are looking for component parts or finished products, we operate 24 hours a day, five days a week, enabling us to provide prompt turnaround on all orders.

A highly-qualified staff, running 28 injection molding presses.

A highly-qualified staff, running 28 injection molding presses.Acorn Thorn Limited

Gloucester GL2 2AF UK

Acorn Thorn is a Morris Group International® partner located in Gloucester, UK. Acorn Thorn is a key manufacturer and supplier of stainless steel commercial sanitary ware to local authorities, schools, hospitals, supermarkets, industrial sites, and prisons.

Acorn Thorn supplies products to meet UK, European, and American specifications, and has customers in more than 20 countries worldwide.

AcornVac Plumbing Systems, Inc.

When AcornVac was founded in 1990, vacuum plumbing's inherent security advantages made correctional facilities a natural area of focus, while its flexibility made it an ideal solution for grocery stores. Today, however, we have a presence in almost every market.

This widespread presence is because architects, building owners, and contractors understand the value of vacuum plumbing. It is a portable, flexible plumbing infrastructure that offers solutions for challenging projects. Those challenges can be due to site conditions, structural issues, or even just tenants who cannot be disrupted by construction going on above them.

This modular building is paired with a modular vacuum plumbing system. Vacuum plumbing offers future-ready flexibility for any type of construction.

This modular building is paired with a modular vacuum plumbing system. Vacuum plumbing offers future-ready flexibility for any type of construction.Healthcare institutions favor AcornVac® systems because vacuum plumbing promotes a healthier environment. Our waste piping doesn't leak, and our toilets do not produce unsanitary flush plumes.

We believe that as more people discover the convenience of vacuum plumbing, it will be the new basis of design for plumbing and drainage.

AcornVac® vaccum plumbing system puts plumbing where you need it, when you need it.

AcornVac® vaccum plumbing system puts plumbing where you need it, when you need it.Chronomite Laboraties, Inc.

City of Industry, CA 91744 USA

Since 1966, Chronomite has engineered and manufactured point-of-use electric water heaters for the commercial and residential markets.

Every single part of our robust, energy-efficient water heaters is made right here, in North America, by us. This means components, such as flow switch mechanisms, are consistent throughout our entire line of heaters.

The Chronomite® Instant-Flow® C-Micro™ Point-of-Use Water Heater, CM Series, delivers hot water exactly where it's needed, saving space under the wash basin.

The Chronomite® Instant-Flow® C-Micro™ Point-of-Use Water Heater, CM Series, delivers hot water exactly where it's needed, saving space under the wash basin.Not only do our customers—-owners of multi-unit dwellings; hotels; and institutional, hospital, and commercial properties—turn to us for an energy-efficient solution, they recognize our safety value as well.

Chronomite® water heaters add a layer of protection against the spread of Legionella, a growing problem around the world. Lukewarm standing water is an ideal breeding ground for this dangerous bacteria. By heating water at the point of use, Chronomite water heaters minimize the amount of warm water lying in the pipe and help to prevent the spread of Legionella.

The Chronomite® Instant-Flow® Micro Electric Point-of-Use Water Heater, M Series, supplies endless hot or tepid water for single and multi-user wash basins.

The Chronomite® Instant-Flow® Micro Electric Point-of-Use Water Heater, M Series, supplies endless hot or tepid water for single and multi-user wash basins.ConTrols Manufacturing

Lake Bluff, IL 60044 USA

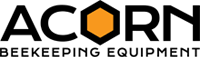

When we launched ConTrols® valves in 2013, we didn't just want to improve on what was already available. Our goal from the very beginning was to start from scratch and re-think water regulation valves completely.

Our full line of water regulating products includes pressure regulating valves, thermostatic mixing valves, whole-building solutions for regulation and monitoring, and more.

TempFlow® thermostatic zone balancing valve independently adjusts and balances flow and temperature in each zone. Model Nos. TZV Series shown.

TempFlow® thermostatic zone balancing valve independently adjusts and balances flow and temperature in each zone. Model Nos. TZV Series shown.Today, our focus is on digital solutions that alert the building owner to problems of which they would otherwise be unaware. This way, instead of performing maintenance on a fixed schedule whether the equipment needs it or not, maintenance is only performed when required, reducing costs for building owners even further.

ConTrols products ensure safety and comfort in schools, hospitals, office buildings, hotels, and other commercial and institutional buildings. They are known for their reliability, easy maintenance, and low cost.

Pressure Reducing Valves available in full range of standard sizing. RV03B SERIES shown.

Pressure Reducing Valves available in full range of standard sizing. RV03B SERIES shown.Croker Fire Prevention

In 1911, Chief Edward F. Croker left the New York City Fire Department after 27 years of service, as a result of the tragic Triangle Shirtwaist Factory Fire. He felt that his experience would be best put to use aiming to prevent and stop fires, rather than simply responding to them once they'd happened. Croker® Fire Prevention was formed in New York in that same year.

For more than a century, Croker manufactured a wide range of fire protection products, including fire extinguishers, valves, cabinets and access panels, monitors, sprinkler products, and more. Croker joined Morris Group International in 2020 as part of the Fire-End and Croker Corporation acquisition.

HEADQUARTERED IN ELMSFORD, NY, TECHNICAL ASSISTANCE IS ONLY A PHONE CALL AWAY, THANKS TO OUR NETWORK OF REPRESENTATIVES NATIONWIDE.

HEADQUARTERED IN ELMSFORD, NY, TECHNICAL ASSISTANCE IS ONLY A PHONE CALL AWAY, THANKS TO OUR NETWORK OF REPRESENTATIVES NATIONWIDE.Elmco + Associates

The Earl L. Morris Company (ELMCO) was founded in 1945 by Earl L. Morris. Elmco®+ Associates became a part of the Elmco® family in 1976. Since then, the company has represented plumbing manufacturers, including of Morris Group International® divisions and partnerships. Located in Hayward, CA and Sacramento, CA, Elmco®+ Associates serves customers in Northern California and Northern Nevada with dedicated sales and customer service staff.

Elmco + Associates represents the best brands for specifiers in Northern California and northern Nevada.

Elmco + Associates represents the best brands for specifiers in Northern California and northern Nevada.Elmco + Associates is committed to identifying unmet needs in the marketplace, promoting product lines to satisfy those needs, and following through with professional support to ensure customer fulfillment.

We have two office and warehouse location; Hayward, CA and Sacramento, CA, to serve our customers.

We have two office and warehouse location; Hayward, CA and Sacramento, CA, to serve our customers.Elmdor Access Doors and Roof Hatches

City of Industry, CA 91744 USA

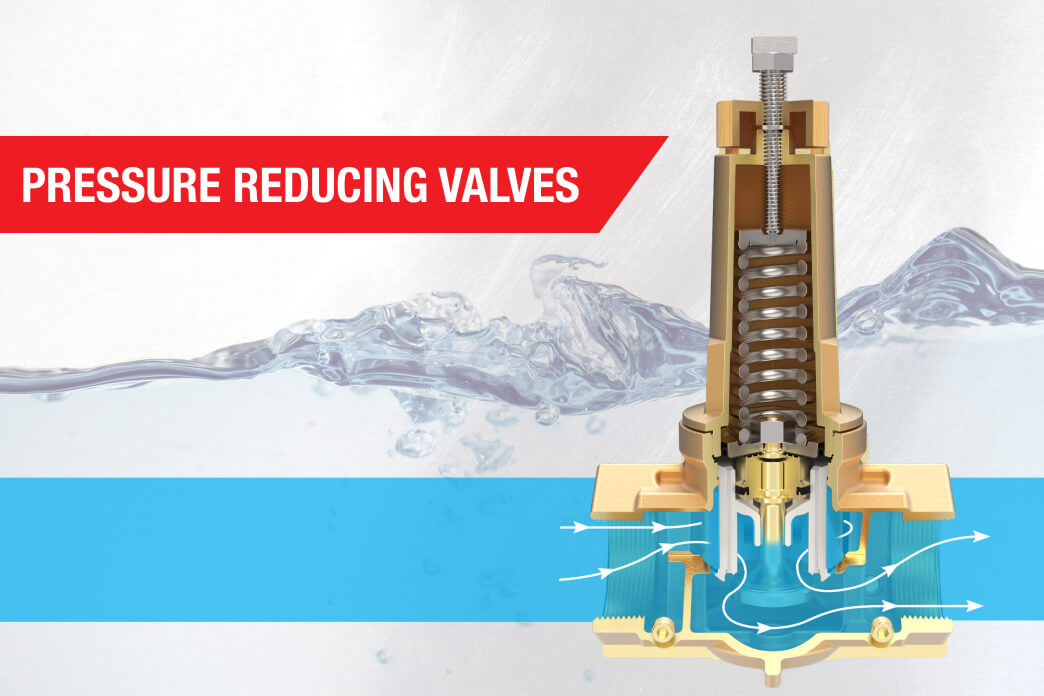

Elmdor® Access Doors provides a quality product, excellent product availability, and top-notch customer service to customers needing access doors and roof hatches. With our extensive inventory and range of stock available, we can have your product on a truck the same day you order it.

Besides stock orders, we welcome and accommodate custom orders. Every door we make starts in our North American factories as a custom sheet of steel. It is then fabricated, boxed, and shipped from the same location.

Elmdor has a wide variety of access doors for most any application.

Elmdor has a wide variety of access doors for most any application.We intend to continue producing high-quality stainless steel products that our customers love. We will also continue investing in new product development and expanding to new markets to serve our customers no matter where their project is located.

Elmdor's warehouse has ample inventory of access doors ready to ship to our customers.

Elmdor's warehouse has ample inventory of access doors ready to ship to our customers.Elmco Silver State

Las Vegas, Nevada 89139 USA

Elmco® Silver State is the newest member of the Elmco family. Located in sunny Las Vegas, NV, Elmco Silver State is committed to being one of the nation's top manufacturer's representatives for specification-oriented commercial plumbing, mechanical, and industrial products.

We are located in sunny Las Vegas, NV!

We are located in sunny Las Vegas, NV!Elmco Silver State caters to engineers, wholesalers, and contractors and consistently provides valuable plumbing knowledge from residential plumbing experts and customer service representatives.

Located in Las Vegas, NV and committed to serving the S. Nevada market.

Located in Las Vegas, NV and committed to serving the S. Nevada market.Elmco Swords

Elmco® Swords, located in Waipahu, HI, serves the Hawaiian Islands with cutting edge plumbing and mechanical solutions from the finest plumbing manufacturers.

Located in beautiful Waipahu, HI.

Located in beautiful Waipahu, HI.The company's track record of providing exceptional customer service has led to strong ties with the local Hawaiian communities and long-lasting partnerships with key contractors and wholesalers.

We represent MGI brands in the Hawaiian Islands, such as Jay R. Smith Mfg. Co., Whitehall Manufacturing, Chronomite Laboratories, and Neo-Metro by Acorn.

We represent MGI brands in the Hawaiian Islands, such as Jay R. Smith Mfg. Co., Whitehall Manufacturing, Chronomite Laboratories, and Neo-Metro by Acorn.Elmco Stewart

Phoenix, Arizona 85009

Elmco Stewart has three United States offices: City of Industry and San Diego, CA; and Phoenix, AZ. Elmco Stewart is a manufacturer's representative for specification-oriented commercial plumbing, mechanical and industrial products since its inception in 1945.

Elmco Stewart's facility in City of Industry, California

Elmco Stewart's facility in City of Industry, CaliforniaElmco Stewart customers include engineers, wholesalers and contractors. Elmco® Stewart is committed to providing excellent customer service, including in-house and field commercial and residential plumbing experts.

Here to serve with locations in Los Angeles and San Diego, CA.

Here to serve with locations in Los Angeles and San Diego, CA.FireEnd

FireEnd® Products was established in 1930 to supply fire extinguishers and other firefighting equipment throughout New York City and the surrounding region.

Since then, it has grown to supply not only fire protection products, but all sorts of professional safety equipment for firefighting, EMS, law enforcement, and military uses. Its products are used around the world.

In 1959, FireEnd Products purchased the Croker Corporation, and the two companies became FireEnd and Croker Corporation. They joined the Morris Group International® family of companies in 2020.

"When a man becomes a fireman his greatest act of bravery has been accomplished. What he does after that is all in the line of work." - Chief of Department — Edward Croker, FDNY

"When a man becomes a fireman his greatest act of bravery has been accomplished. What he does after that is all in the line of work." - Chief of Department — Edward Croker, FDNYFire Pro Nozzles and Monitors

City of Industry, CA 91746 USA

Since our inception in 1979, Fire Pro's mission has been to manufacture quality fire protection products at an affordable price with short, reliable lead times. Our mission remains the same today and is part of what makes us a thriving division of Morris Group International.

Our monitors are essential fire protection equipment in the mining industry, oil refineries, marine applications, wastewater plants, wildland vehicles, chemical and petrochemical settings, and more—but our equipment is also used for dust abatement, cleaning, and many other tasks that require precise, high-flow water delivery.

Fire Pro monitors provide precise, high-flow water delivery, making them essential fire protection equipment in many industries.

Fire Pro monitors provide precise, high-flow water delivery, making them essential fire protection equipment in many industries.We recognize that every application needs the right solution. For many customers, we can meet their needs with one of our standard, existing products. For others, we will go out of our way to design and create a custom product that precisely addresses their needs.

From conceptualization and design to installation, calculation, troubleshooting, and even maintenance, we're happy to work with you. If you need 100 units or a one-off, custom-tailored system, we guarantee you the best in support, reliability, and value.

Fire Pro manufactures a wide variety of monitors and accessories to work with many applications; custom products can be made for unique applications.

Fire Pro manufactures a wide variety of monitors and accessories to work with many applications; custom products can be made for unique applications.Larsen's Manufacturing Co.

Larsen's is one of the oldest and most experienced fire equipment cabinet manufacturers in the United States. The company began in the 1930s as a sheet metal job shop, but in the 1960s we created our own brand line of fire cabinets that were both effective and beautiful, unlike the other products on the market at the time.

Over the years, we have been continually innovating with materials, design options, and specialized features for specific applications. This has made our fire extinguisher cabinets a true architectural piece of equipment and a favorite of building owners, designers, and architects.

However, people do not specify Larsen's® cabinets just because they are pretty to look at. They turn to us because we offer an unsurpassed level of quality across our entire product line. That line now includes fire extinguisher cabinets, fire hose and valve cabinets, access panels, detention equipment, and marine industrial and fire equipment.

While we are expanding and opening a new manufacturing facility to meet increased demand, we hold on to our small-business roots. One call gets you all the answers you need.

The Larsen's® product line includes fire extinguisher cabinets, Flame-Shield® fire-rated cabinets, access panels, fire hose/valve cabinets, and heavy gauge cabinets and access panels for detention facilities.

The Larsen's® product line includes fire extinguisher cabinets, Flame-Shield® fire-rated cabinets, access panels, fire hose/valve cabinets, and heavy gauge cabinets and access panels for detention facilities.Jay R. Smith Mfg. Co.

Montgomery, AL 36109-1405 USA

Today, Jay R. Smith Mfg. Co. boasts more than 65 service centers around the world, but in 1926, it was just an idea. A salesman for the National Lead Company, Jay L. Smith, saw a market need for quality plumbing products. He enlisted the aid of his son, Jay R. Smith, and an industry leader was born.

Today, Smith produces a wide range of innovative plumbing products spanning everything from floor drains to electronic trap primers. Thanks to our long history in the industry and the expertise of our engineers, we understand many of the challenges facing our customers. Our Labor Saver® line is specially designed to minimize many of these frustrations.

We at Smith pride ourselves on being customer driven. We never turn down a challenge, especially when it offers us the opportunity to create a custom product to fit a customer's needs. No matter what that challenge is, we rise to meet it.

These labor-saving and value-added products are designed with contractors and installers in mind.

These labor-saving and value-added products are designed with contractors and installers in mind.Morris Group International® Innovation Center

The Morris Group International® Innovation Center is dedicated to a principle first expressed by Earl L. Morris, Founder, "There is no substitute for quality." That sentiment has remained with us since 1954.

We don't simply stand behind the quality pledge; we have constructed and invested in Morris Group Innovation Centers (MGIC) in Los Angeles, CA; Chicago, IL; and Montgomery, AL. The MGIC hubs research, develop, and test products for all 28 Morris Group International® (MGI) divisions, including Acorn Engineering Company®, Jay R. Smith Mfg. Co.®, ConTrols®, Murdock Manufacturing®, AcornVac, Inc.®, Whitehall Manufacturing®, Elmdor Manufacturing®, Safety Manufacturing®, Chronomite, Inc.®, Potter-Roemer®, Fire-Pro®, Acorn Beekeeping Equipment®.

The divisions encompassing MGI have a combined business experience of more than a millennium, growing despite the economic conditions by investing in technology, focusing on core strengths, and experimenting with new products and revenue streams.

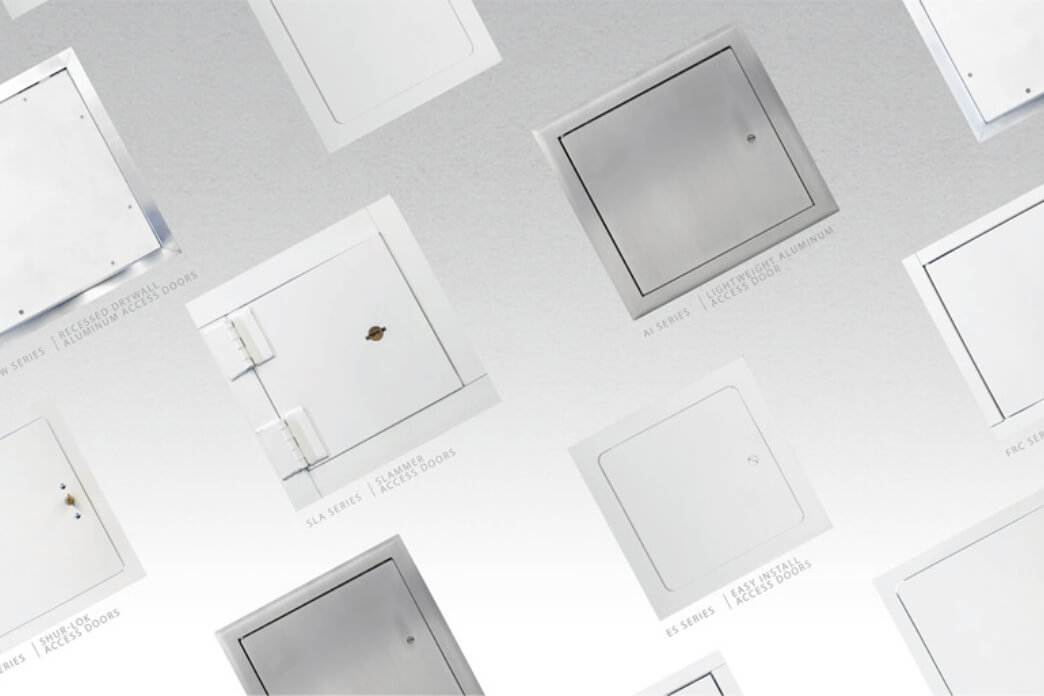

Cutting-edge technology aids in designing, engineering, and testing new products.

Cutting-edge technology aids in designing, engineering, and testing new products. The Innovation Centers emerged out of necessity in reaction to the COVID-19 pandemic. The commercial market was dwindling for principal institutional products, and MGI needed to shift focus to the opportunities of the time.

This was "one of the most innovative periods in our history," according to Donald E. Morris, CEO of Morris Group International. "We came together; we collaborated with sales, marketing, manufacturing, purchasing, and engineering, and we came up with a whole line of hand-washing products. We could move quickly on this product line because we worked together; it was a primary competency. We innovated hand-washing products; we designed, manufactured, and shipped them with sales, engineering, and marketing materials within six to nine months. It was incredible. That is the innovation spirit of Morris Group."

Pressure-reducing valves are the latest product group emerging from our state-of-the-art facilities. In 2024, with the help of MGIC, the ConTrols® division will introduce a line of backflow preventers. The MGIC has also sparked new product development at Acorn Engineering Company and Jay R. Smith Mfg. Co. MGIC invests further in equipment and expertise to keep new products coming. “Our core products help support the innovation of new products,” says CEO Don Morris. Coming from Acorn in 2024 is the Acorn-Sinks product line: an all-new collection of stainless steel commercial sinks. Plenty more inventive products from the Innovation Centers are planned for years to come.

"We make our stuff. We have it in inventory. And if we don't have it in inventory, we can quickly turn it around. We control our destiny." - Donald E. Morris, CEO

Sustained investment in technology, coupled with the utilization of an outdoor testing facility, positions MGI at the forefront of the industry.

Sustained investment in technology, coupled with the utilization of an outdoor testing facility, positions MGI at the forefront of the industry. Consistent re-investment in technology keeps MGI at the front of the pack.

Consistent re-investment in technology keeps MGI at the front of the pack.The product development from the Morris Group Innovation Centers significantly changes how we go to market and how our customers do business with us. To close with the words of our CEO, Don Morris: “What keeps the ideas coming is talking to lots of people, and not only talk, but listen to their ideas, watch the trends, and think about the people’s need…keep your eyes and ears open.”

MY LEGACY IS NOT EXTINCTION. MY LEGACY IS PROSPERITY AND STRENGTH.

We are a company that grows. We grow by enhancing our brands. We drive our business with new products, engineering, and uniqueness. If no new products exist, we suffer in the future.

— Donald E. Morris,CEO, Morris Group International

Morris International ME FZE

Office # 1608

Mazaya Business Avenue BB1

Jumairah Lake Tower, Dubai United Arab Emeritus

Morris International ME FZE is Middle Eastern sales representative and distribution partner of Morris Group International. Located in the heart of Dubai, Morris International ME FZE provides plumbing, mechanical, and industrial products to contractors, wholesalers, engineers, and end users.

Our specification-oriented commercial plumbing, mechanical and industrial products are sold across the Middle East.

Our specification-oriented commercial plumbing, mechanical and industrial products are sold across the Middle East.Morris International ME FZE distributes throughout the Middle East, enabling manufacturers to extend their reaches across international borders and work on a global scale.

Located in the heart of Dubai, Morris International ME FZE is a representative and distribution partner of Morris Group International and other elite manufacturers.

Located in the heart of Dubai, Morris International ME FZE is a representative and distribution partner of Morris Group International and other elite manufacturers.Fabricación y Manufacturas de México

Industrial Tijuana, B.C., C.P. 22444 Mexico

Fabricación y Manufacturas de México S.A. de C.V. is the Mexican manufacturing facility of Morris Group International. With 600 employees and 400,000 square feet of manufacturing and office space, F&M México provides essential manufacturing power to Morris Group International.

F&M México specializes in products fabricated from stainless and galvanized steel, terrazzo, plastic, solid surface materials, and cast iron. Our manufacturing capabilities include fabrication, assembly, wet and powder coating, and polishing. Products made at F&M México are distributed throughout Mexico by Morris Industries Mexico.

We pride ourselves in our ability to create high-quality, unique, custom solutions for customer needs. Morris Industries Mexico supplies fixtures to schools, correctional institutions, and commercial and government buildings.

F&M México has received several awards in recognition of our commitment to quality manufacturing practices, and, with Morris Industries Mexico, continues to lead the industry in producing high-quality, beautiful, and durable fixtures.

Morris Industries Mexico distributes products from Morris Group International divisions and partnerships in Central and South America.

Morris Industries Mexico distributes products from Morris Group International divisions and partnerships in Central and South America.Morris Lee Limited

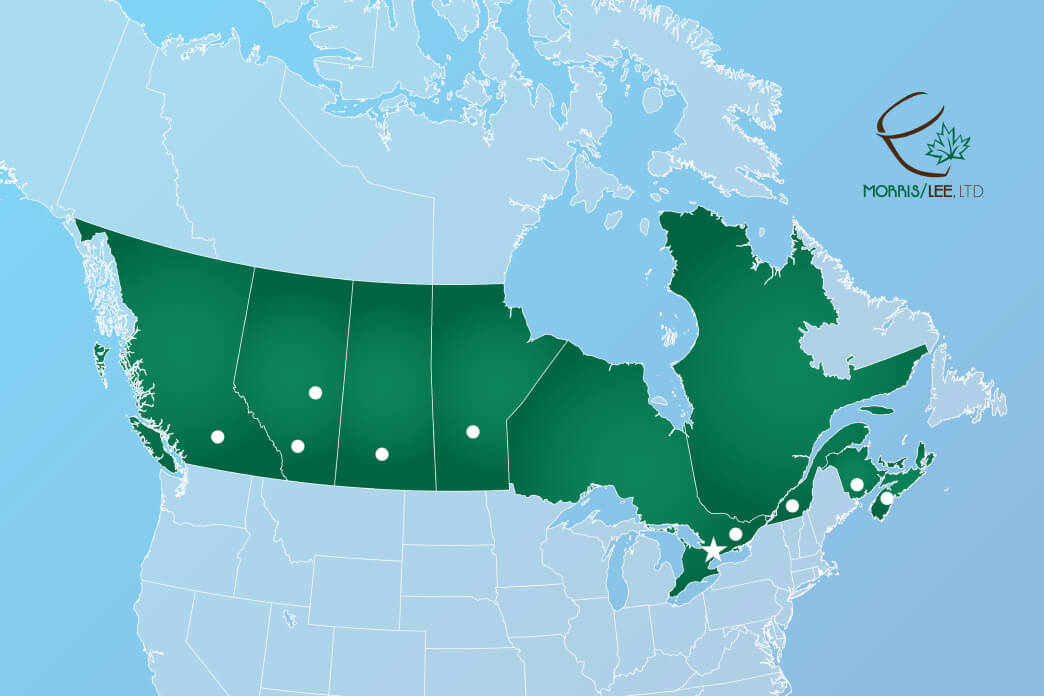

Morris/Lee, Ltd., was founded in 2015 as a manufacturer's representative for specification-oriented commercial plumbing, mechanical, and industrial products for the Canadian market. The company is a joint partnership between Don Morris, President and CEO of Morris Group International, and Jim Lee, the Managing Director of Morris/Lee, Ltd.

Morris/Lee, Ltd. headquarters in Ontario, Canada.

Morris/Lee, Ltd. headquarters in Ontario, Canada.Morris/Lee, Ltd., leverages the strengths and business model of Morris Group International to bring expanded representation services to Canada, with more product lines, higher quality customer service, and faster shipment.

Covering all of Canada from our headquarters in Toronto, ON.

Covering all of Canada from our headquarters in Toronto, ON.Morris Industries Mexico

Industrial Tijuana, B.C., C.P. 22444 Mexico

Morris Industries Mexico is the distributor of Morris Group International® products in Central and South America. We distribute products to commercial, institutional, and governmental customers. Our use of durable materials such as stainless steel means that our products stand up to heavy traffic, and many products can be customized with optional colors and finishes.

Morris Industries Mexico distributes products from Morris Group International divisions and partnerships in Central and South America.

Morris Industries Mexico distributes products from Morris Group International divisions and partnerships in Central and South America.Central to the success of Morris Industries Mexico is the quality of our products. Our products are manufactured by our Mexican manufacturer, Fabricación y Manufacturas de México S.A. de C.V. (F&M). Over the years, F&M has received many awards for its excellent manufacturing practices.

A worker prepares Acorn Engineering Company combys for shipment.

A worker prepares Acorn Engineering Company combys for shipment.Murdock Manufacturing

City of Industry, CA 91746 USA

Murdock is a sixth-generation, family-run company that has always had one goal: access to clean, safe, drinking water for all. We've been in business since 1853, and, to this very day, when you call us you can still get a Murdock on the phone.

When you turn to us for water delivery products—be they drinking fountains, water bottle fillers, hand washing stations, water coolers, or hydrants, you get the benefit of all those decades of experience and innovation.

Our drinking fountains have kept families hydrated since 1853. Our Classic Series has a tulip filigree-style pedestal and bass polished bowl and bubbler.

Our drinking fountains have kept families hydrated since 1853. Our Classic Series has a tulip filigree-style pedestal and bass polished bowl and bubbler.No matter where you go in the world, you've probably encountered a Murdock® product. Maybe you've had a drink from a drinking fountain installed at the turn of the 20th century or filled your bottle from a high-tech, touchless bottle filler.

We continue to develop high-quality, innovative products that ensure everyone has access to clean, safe water.

Touchless H2O-To-Go!® bottle fillers are ideal for schools and places where people gather.

Touchless H2O-To-Go!® bottle fillers are ideal for schools and places where people gather.Potter-Roemer

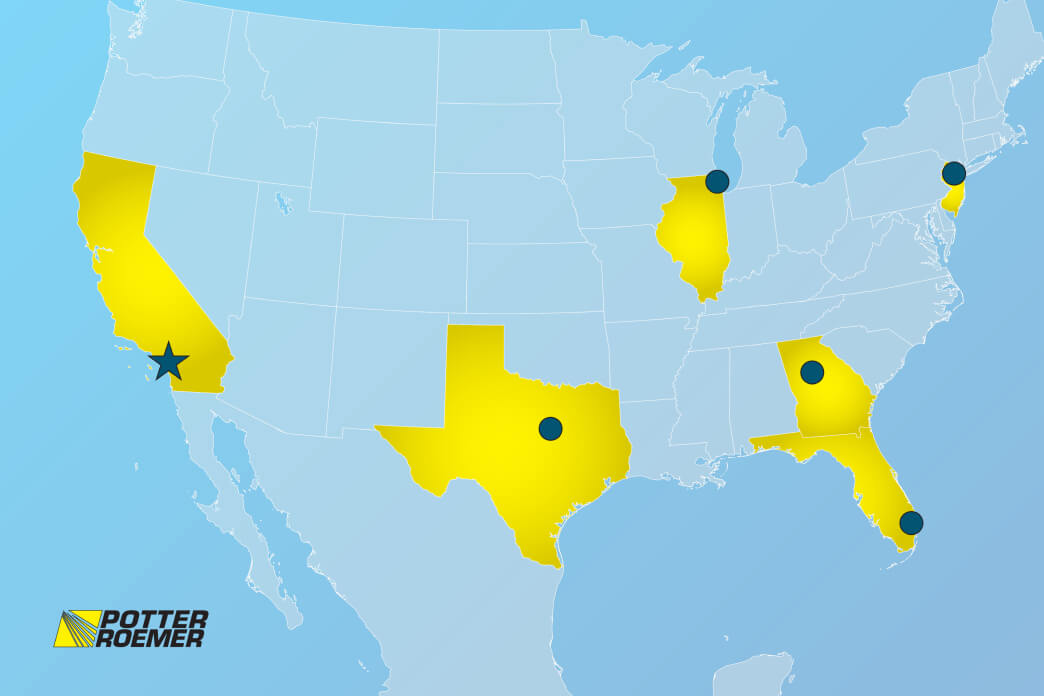

Potter Roemer's history is very similar to that of Acorn Engineering Company. We started in 1937 as a manufacturer's representative agency, but in our case, we were representing fire protection equipment.

Today, Potter Roemer is the recognized leader in fire protection equipment. In industrial, commercial, institutional, and high-rise buildings, water pressure control is crucial for fighting fires. Installing contractors of these types of structures turn to us for their fire protection needs.

The Potter Roemer® product family includes cabinets, fire extinguishers, hoses, valves, connections, equipment houses, and specialties.

The Potter Roemer® product family includes cabinets, fire extinguishers, hoses, valves, connections, equipment houses, and specialties.The advantage of Potter Roemer® products is that we engineer and manufacture all of their components, starting with a sheet of metal. Our sheer size allows us to dictate the best prices for our customers.

We like to think of ourselves as an old company with young ideas. We are always looking for ways to improve our current line and add new items to our offerings based on the needs of our customers and the contractor.

Providing fast, efficient, shipping and service from a location near you.

Providing fast, efficient, shipping and service from a location near you.Safety Manufacturing

City of Industry, CA 91746 USA

Safety Manufacturing is a proud manufacturer of the industry's leading emergency drench equipment and safety plumbing products. Customers in pharmaceuticals, manufacturing, utility and maintenance rooms, laboratories, and more turn to us because of the reliability of Safety Manufacturing™ products.

Our safety showers and eye wash stations are constructed of stainless steel and anti-microbial plastics. Most notably, all our safety products include the most reliable and effective digital emergency tempering system on the commercial market.

A Safety Manufacturing eyewash can flush the eyes after exposure to chemicals and contaminants.

A Safety Manufacturing eyewash can flush the eyes after exposure to chemicals and contaminants.A safety shower or eye wash station is something you hope you never need to use, but it is crucial that it works when you need it. We understand and value the importance of these products, and we will continue to invest in new technology. Enhancements such as automatic testing and alerts are on the horizon, which will provide our customers with additional protection.

Safety Manufacturing™ emergency showers protect workers by washing away harmful substances in a workplace emergency.

Safety Manufacturing™ emergency showers protect workers by washing away harmful substances in a workplace emergency.Smith Chrome Plating

Montgomery, AL 36109-1405 USA

Smith Chrome Plating and Polishing Services provides decorative chrome plating for products as diverse as antiques; automotive and motorcycle parts; dental, surgical and hospital equipment; retail displays, and more.

We provide decorative chrome plating services for a wide variety of industries and uses, including antiques, automotive and motorcycle parts, medical, fire protection, food processing, and retail display equipment.

We provide decorative chrome plating services for a wide variety of industries and uses, including antiques, automotive and motorcycle parts, medical, fire protection, food processing, and retail display equipment.For more than 60 years, we have offered a variety of plating processes and finishes to our valued customers. We have a competitive spirit and a dedication to quality and excel in custom work.

Our polishing services create a perfect shine for steel, stainless steel, copper, brass, zinc die cast, aluminum, and many more metals and services.

Our polishing services create a perfect shine for steel, stainless steel, copper, brass, zinc die cast, aluminum, and many more metals and services.Whitehall Manufacturing

City of Industry, CA 91746 USA

Since 1946, Whitehall Manufacturing has been a leading supplier of medical equipment. Originally a manufacturer of rehabilitative whirlpools for soldiers returning from World War II, we now manufacture and distribute a wide range of products for applications across the healthcare and rehabilitation markets.

BestCare® Ligature-Resistant products balance the need for safety and security with the patients' needs for a healing environment.

BestCare® Ligature-Resistant products balance the need for safety and security with the patients' needs for a healing environment.The Healthcare arm of Whitehall Manufacturing focuses on manufacturing safe, durable plumbing equipment for healthcare applications. We pride ourselves on our attention to universal design and infection prevention. From our ligature-resistant BestCare® line of fixtures and accessories to scrub sinks designed with thoughtful infection prevention features, we focus on safety and user experience.

Whitehall RehabilitationWhirlpools have been a staple of our product lines since 1946. Today our complete line of quality Whirlpools and accessories provide physical therapists and athletic trainers the equipment they need for hydrotherapy.

WHITEHALL™ WHIRLPOOL TANKS ARE OFTEN USED AS COLD TANKS OR ICE BATHS.

WHITEHALL™ WHIRLPOOL TANKS ARE OFTEN USED AS COLD TANKS OR ICE BATHS.